50+

Projects Completed

70000

SF Addition

ISO 4

Cleanroom Space

3200-ton

Chilled Water Plant

24000

MBH Boiler Plant

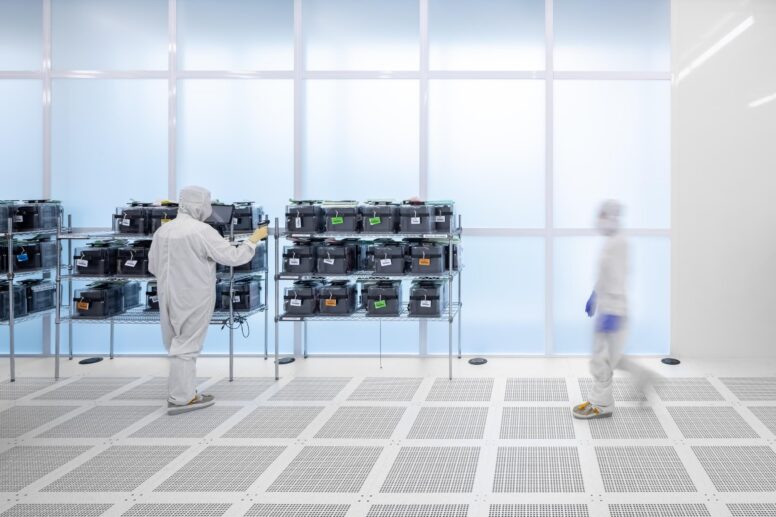

Chip Fabrication Expansion

This project expands the client’s existing microchip manufacturing facility with a 64,000 SF addition and 3,000 SF of renovation. The addition has 5,300 SF of shell space, 10,200 SF of ISO-4 (Class 10) cleanroom, and 9,600 SF of sub-fab space. The cleanroom design features a pressurized supply plenum and fan arrays on each side of the room. The project required extensions to the acid waste neutralization, processed vacuum, processed nitrogen, argon, hydrogen, oxygen, saline systems, etc. A new low-temperature chilled water system and boiler plant support the new addition. The project included a new RO/DI system, which Dunham assisted Smith Engineering in designing, as well as a compressor addition to the CDA system. Dunham provided mechanical and electrical engineering services, commissioning services, as well as tool fit-up MEP design for tools ready to be installed upon completion.

The addition included a new 3,200-ton water-cooled low-temperature chilled water plant. This plant consisted of four 800-ton nominal water-cooled chillers and cooling towers. The new 24,000 MBH boiler plant provides heating water to the building. This plant incorporated four 6,000 MBH condensing boilers. The chilled water and heating water plants were installed in a multi-phase, multi-year project to align with staged manufacturing growth needs. Dunham provided mechanical and electrical engineering services, commissioning services, as well as tool fit-up MEP design for tools ready to be installed upon completion.

Ongoing Partnerships and Projects

- Arc Flash Analysis

- Ongoing Infrastructure Upgrades

- Ongoing Manufacturing Space Design

- Manufacturing Risk Assessment

- Nitrogen Plant Replacement

- SCIF Office Remodel

- Tempest Manufacturing SPace

- Various Tool Installs